Kolpen

-

Posts

96 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Events

Posts posted by Kolpen

-

-

Fantastic, quick and precise! Thanks alot.

Well, I got one more though. Should be closer to my scale (1:16) but not really... I need two wheels for the outer front wheels on the TIGER.

I am searching for the following dimensions:

Outer diameter ca. 48mm

Width ca. 16mm

Tread as pictured or similar:

http://dk.starcoshop.com/pi/10_0_75_15_3…24874_2153.aspx

Thank you very much for any help!

-

Anyone know where to find tractortread tyres measuring;

Ø~49mmWidth ~12mm

They will be used on a 1:16 scale Horsch Tiger AS

Thank you very much

Anders Kolpen

-

Comments are welcome!

Anders Kolpen

-

1

1

-

-

Well, this is actually not my scale as I only operate in 1/16

( http://www.youtube.com/user/akolpen?feature=results_main )

A friend of mine do collect the smaller size though.

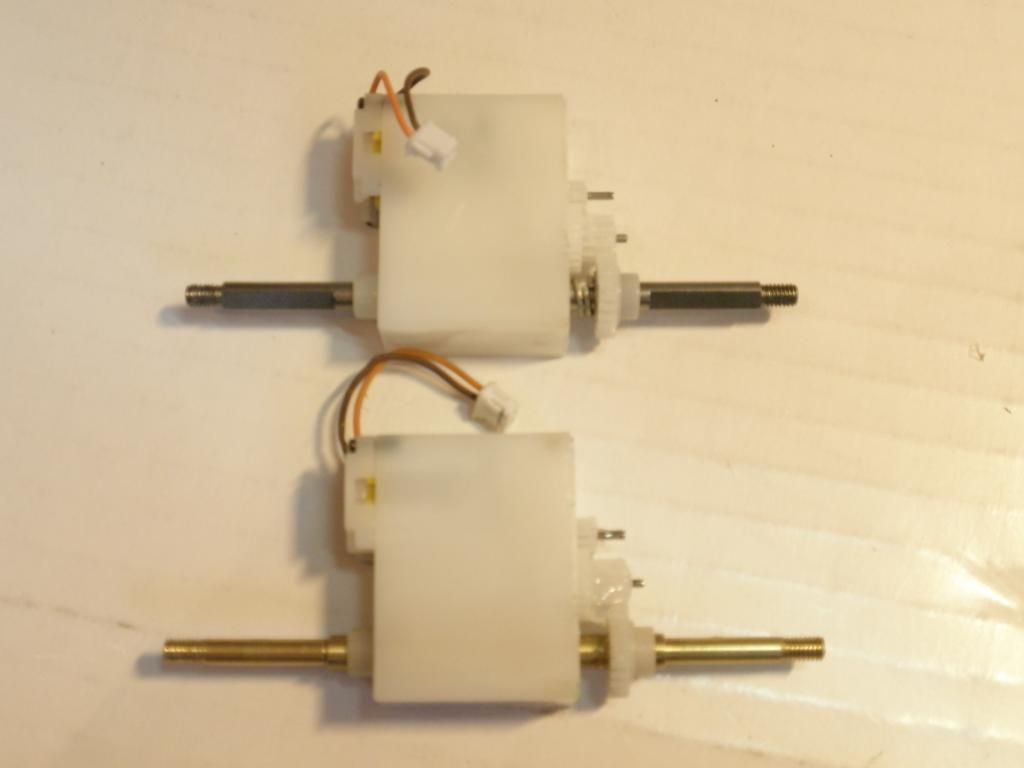

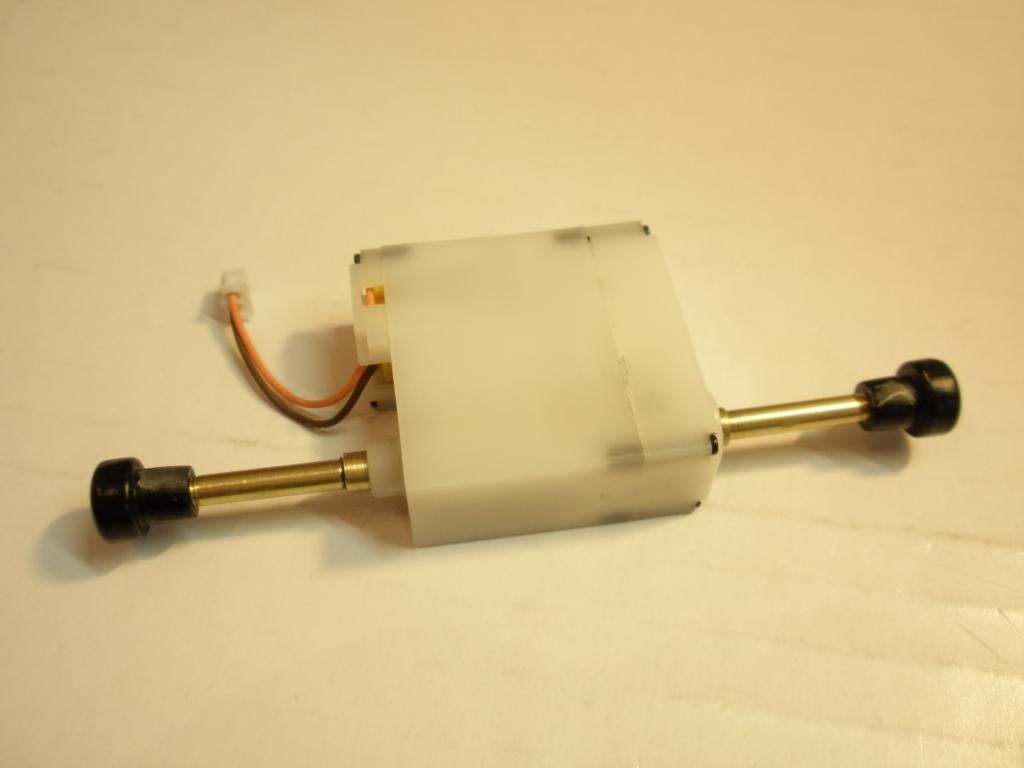

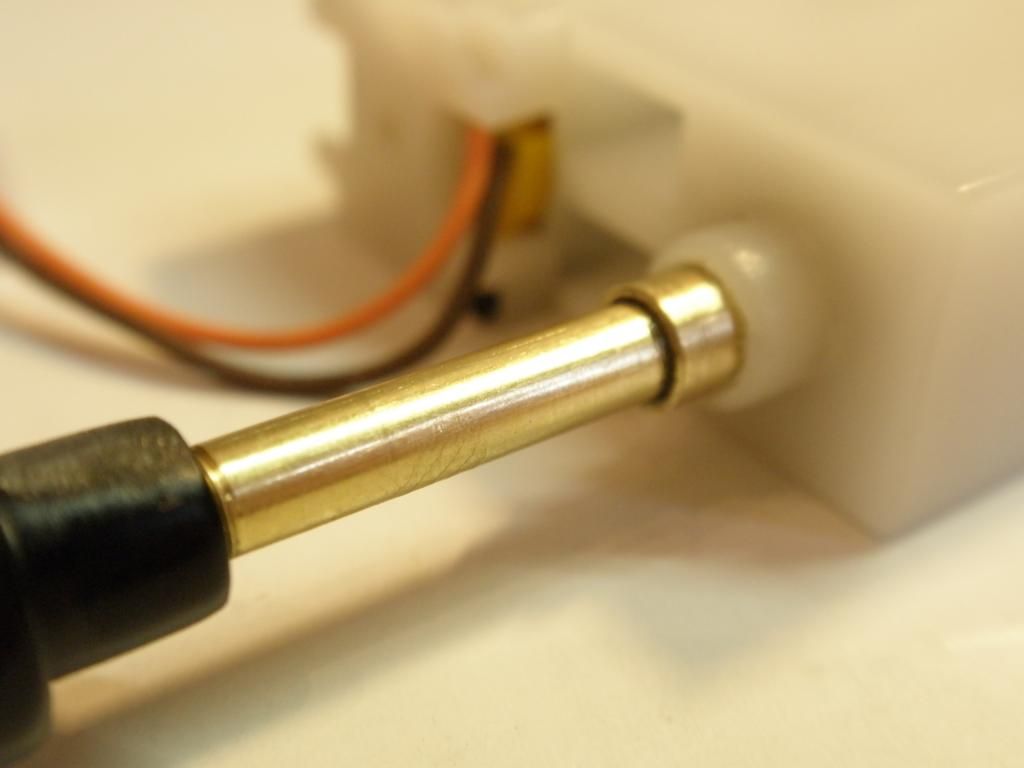

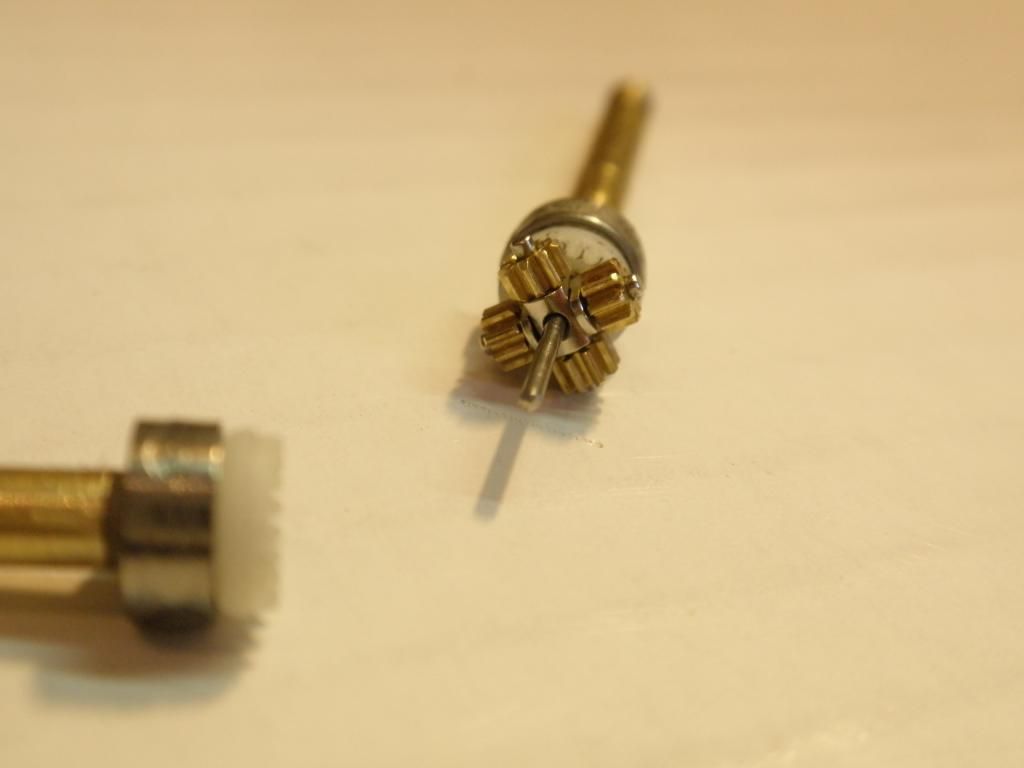

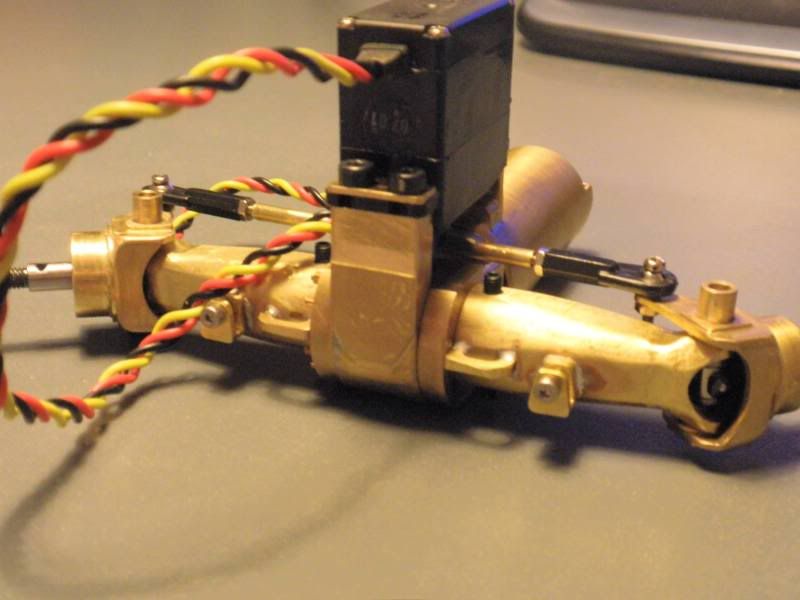

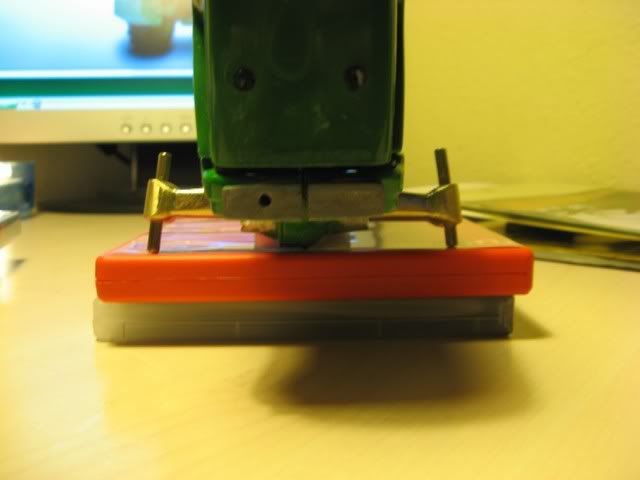

I wanted to do something to these 1/32 scale tractors to steer better.

I already modified the servos to rotate more, giving a tighter turning radius.

Still not enough. A differential is definetly necsessary for a perfect turning.

The problem is that you need a heavy rearend to avoid wheelslip, making it turn really bad, as the locked axle forces the tractor to go straight.

Till now the only you could do is add weight in the front to be able to steer. Now I hope to add weight both in the front but also in the rear.

Still haven't tested it yet, but pictures is here....:

-

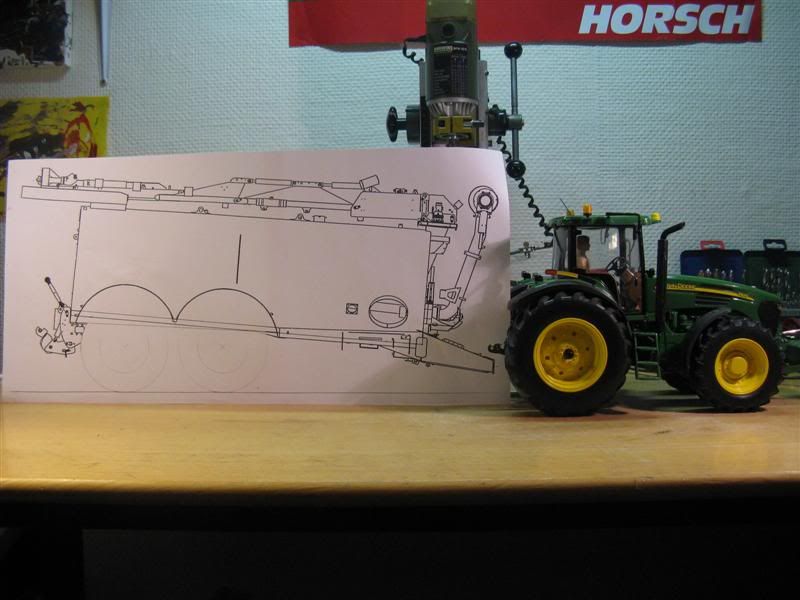

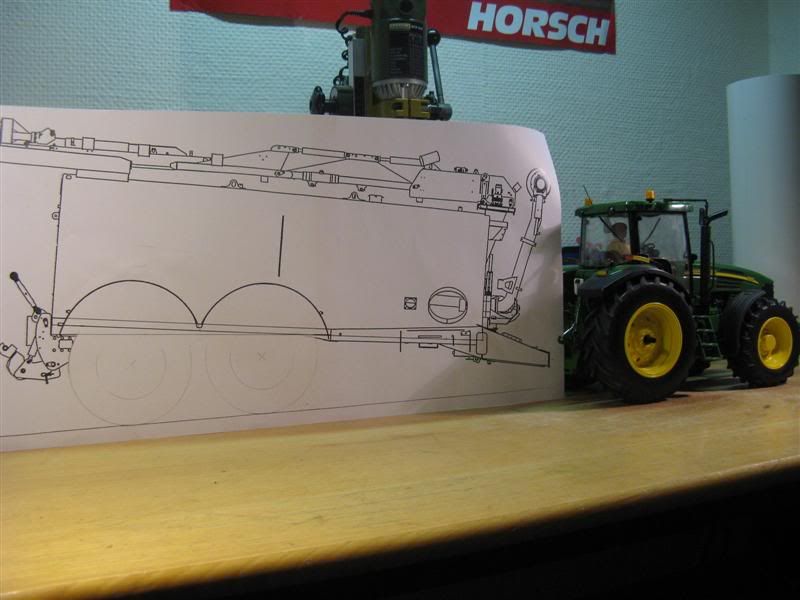

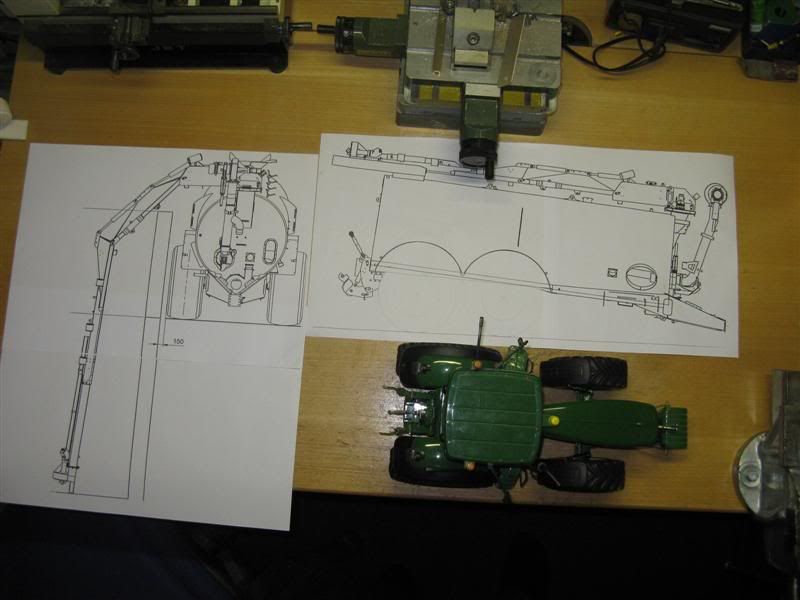

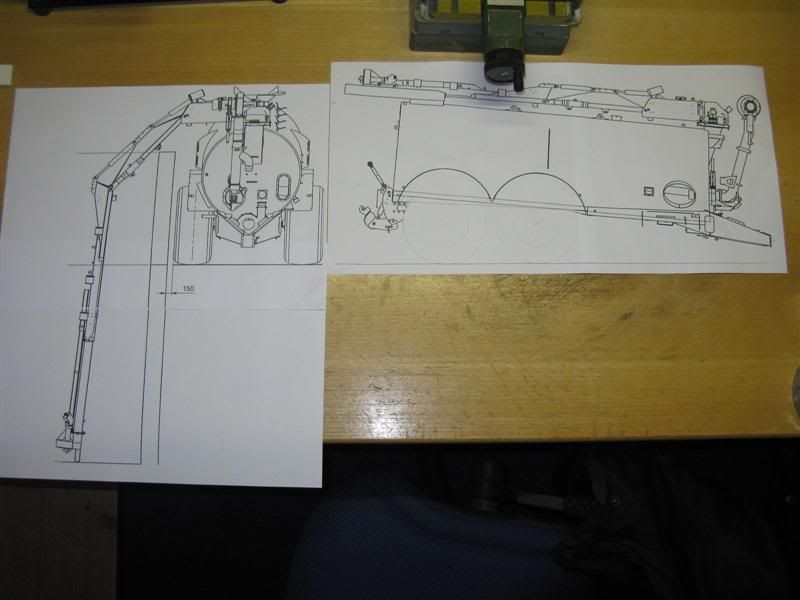

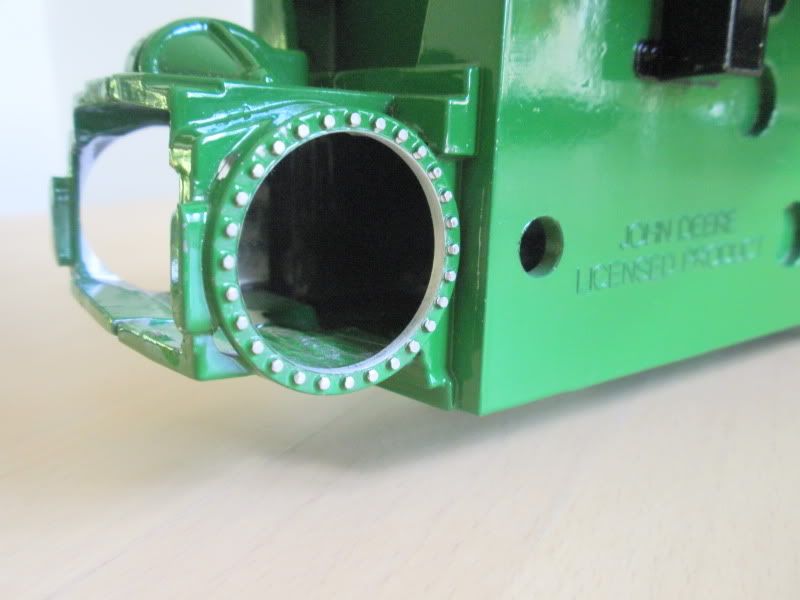

Here is the start of my new project. Actually I’m ‘still’ working on my plow, but I could’nt help it… -this project has been on my mind for years.

I’m planning on building a Danish made slurry tanker by the company SAMSON Agro.

Model: SAMSON PG 20 (20m3)

Video: http://youtu.be/R_rdiiOFGGw

My model will have the following functions;

- Rear 3pt. hitch

- Output for boom (attached to the 3pt) to fold

- Crane

- rotate

- bend x 2

- lift

- Pump

- in

- out

- Electronic steereable rearwheels

- Lights

- normal

- work

- brake

- beacon

- Eventually the frontwheels will be powered (+ 70 hp in real life)

- 4.9 liter

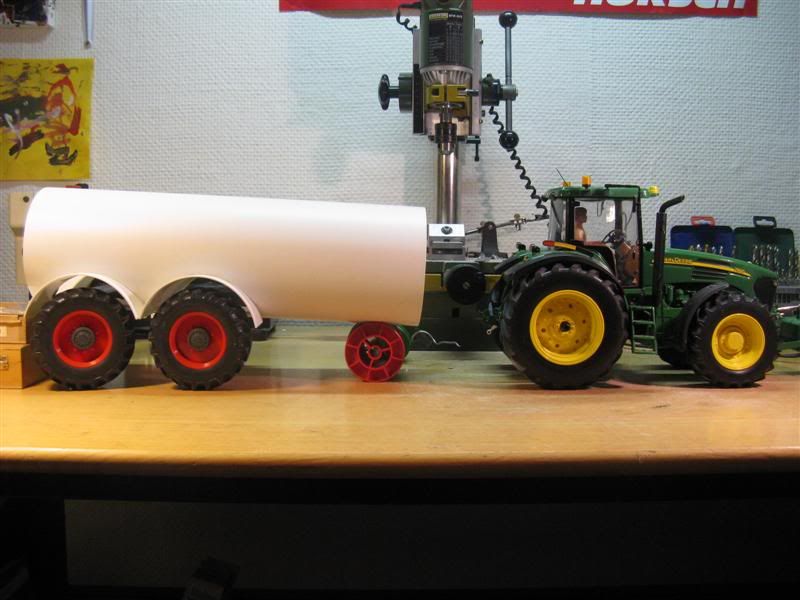

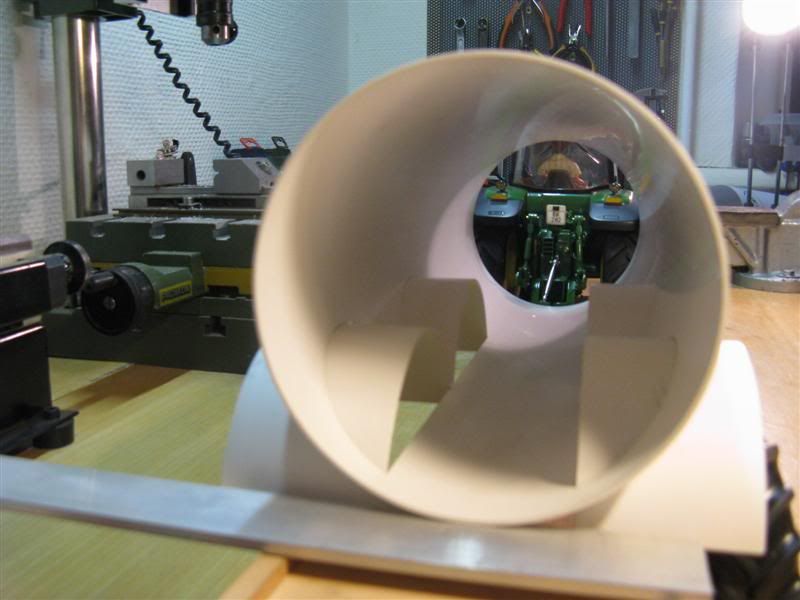

- Plastic tube and fenders rest is brass and aluminum.

The wheels will be changed later, these is just to show how it will look....

For now, as you can see I have only got the tube and fenders. And that’s actually where it will be for a while. I’ll have to continue on my Kverneland 7 furrow plow.

Pictures to start this thread… plenty more to come!

-

1

1

-

-

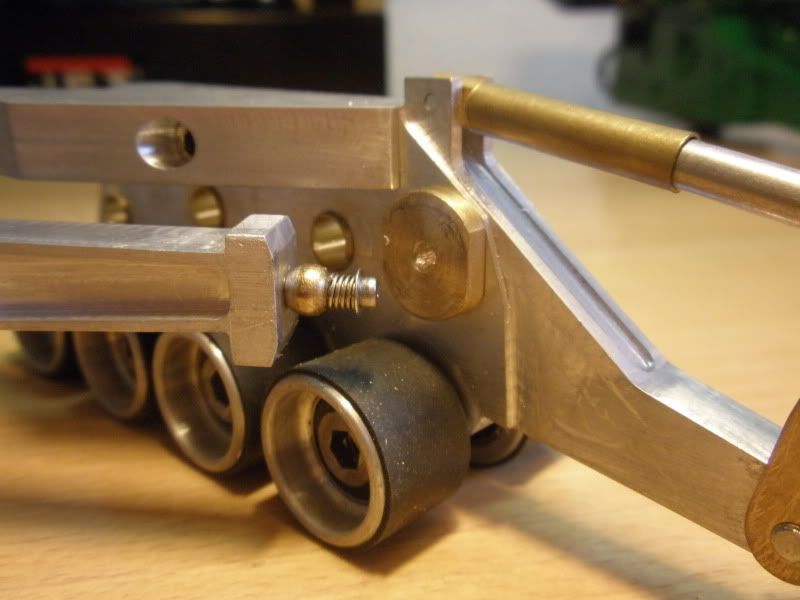

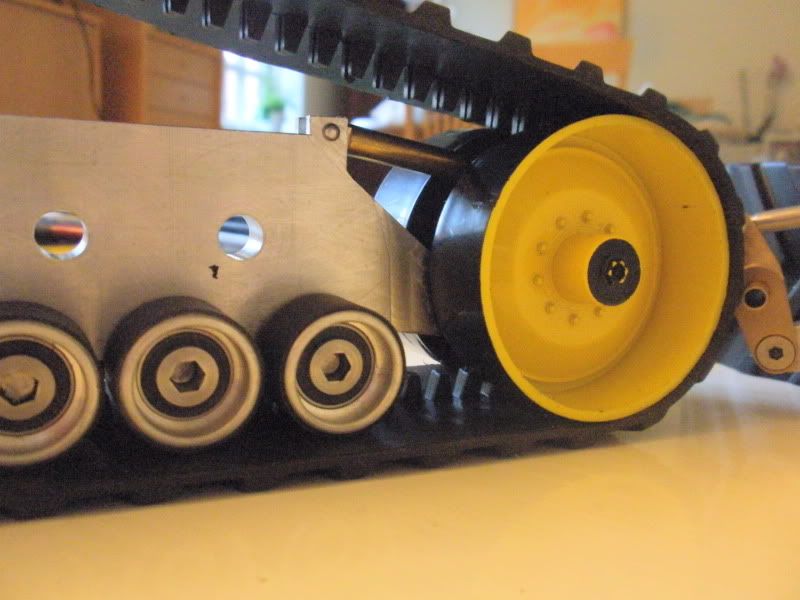

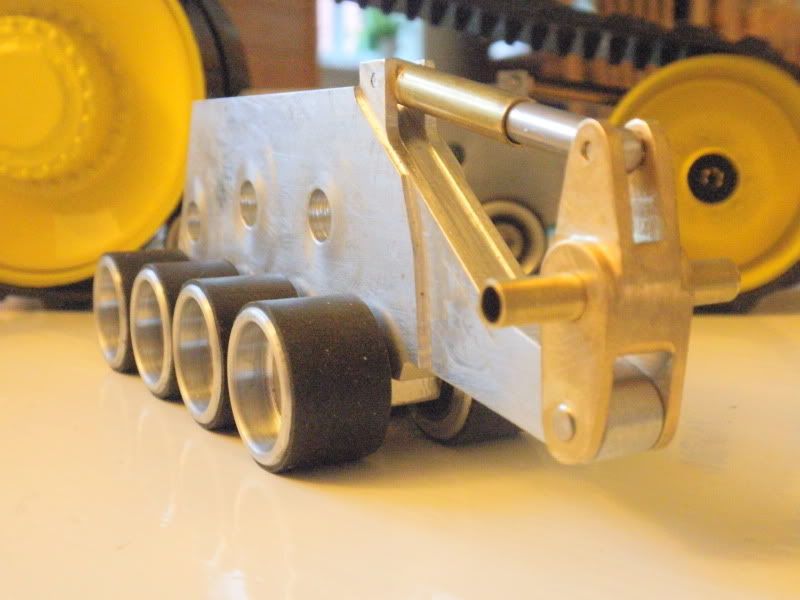

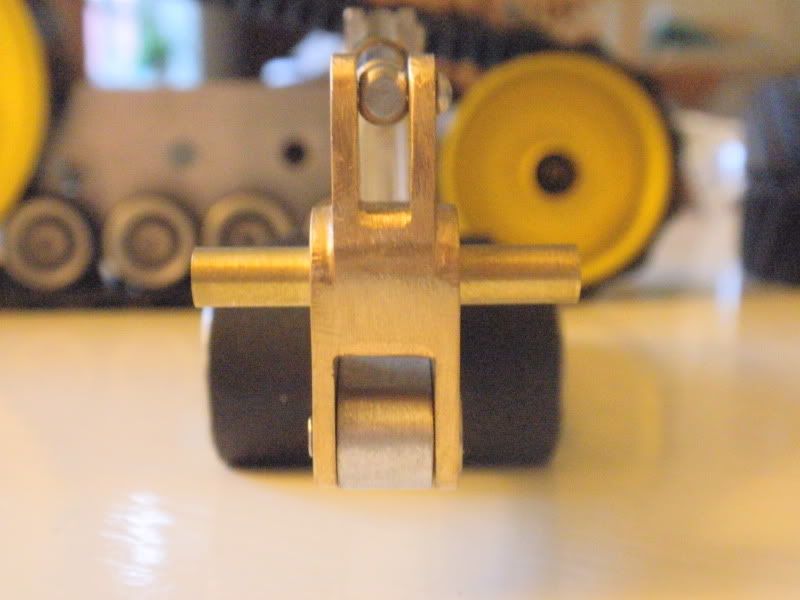

Here is a little progress on the 9020T tractor I am working on.

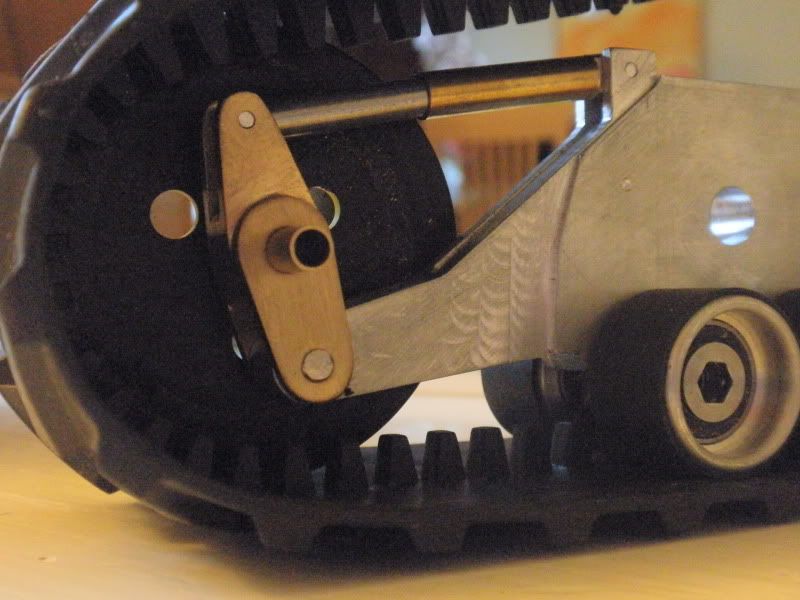

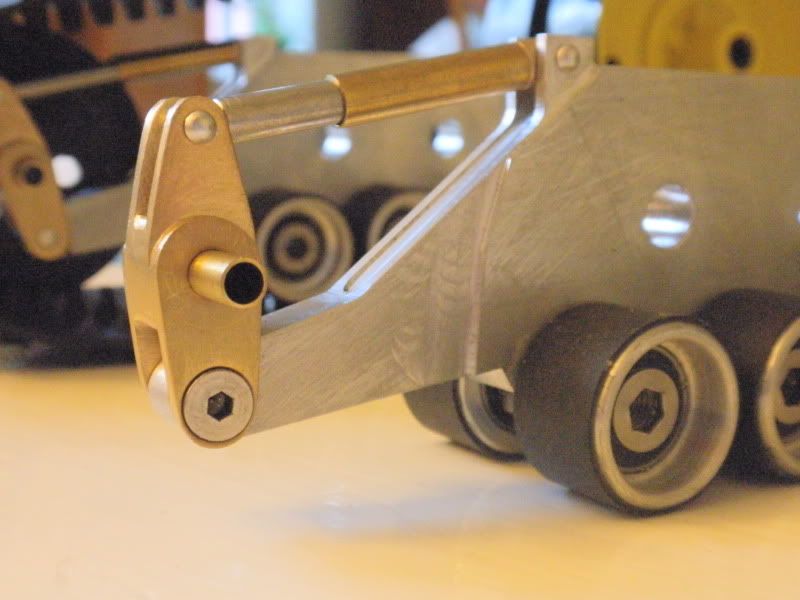

Belttension is a little redesigned with bearings in the 'forks' instead of placing the in the wheels.

The walking beam is now done. On the pictures you will see how I made the attachments to the frames.

The issue is that, by moving the two frames up and down from center/zero the distance is getting bigger and when the beam is attached, it forces the frames to move inward and therefore no longer parallel.

I came up with the idea, that if I let it 'rotate' over a square piece, it would spread the frames when the beam travels up and down. Also the beam will be able to travel backward (about 1.5mm) on the mid axle. As this disatnce also get's shorter.

Next up is the gearbox.

Comments are welcome as usual

)

)

Anders Kolpen

-

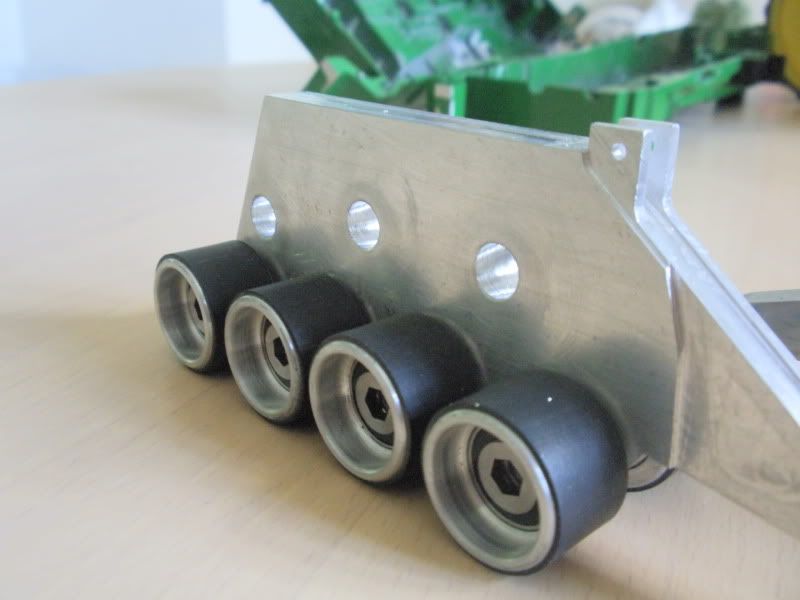

Just a small update

Belt tension is completed. Wheelcaps for the roller wheels is coming soon.

Pictures:

/Kolpen

-

After a longer break with my plow (not finished), I decided to continue with my 9020T tractor.

I recently sold my very first RC conversion, a 9420T, just to start on a new one. This new model will feature a completely homemade undercarriage, with a walking beam and belttension. New tranny with Faulhaber motors and a Servonaut speedcontroller for track vehicles. A swing drawbar OR eventually a 3pt hitch to pull the European equipment…

Here is some pictures on the beginning of the project:

Mainframe is milled out to make room for transmission and rearaxles.

Left and right side of the undercarriage is almost done.

To be continued…..

/Kolpen

-

Hello everybody

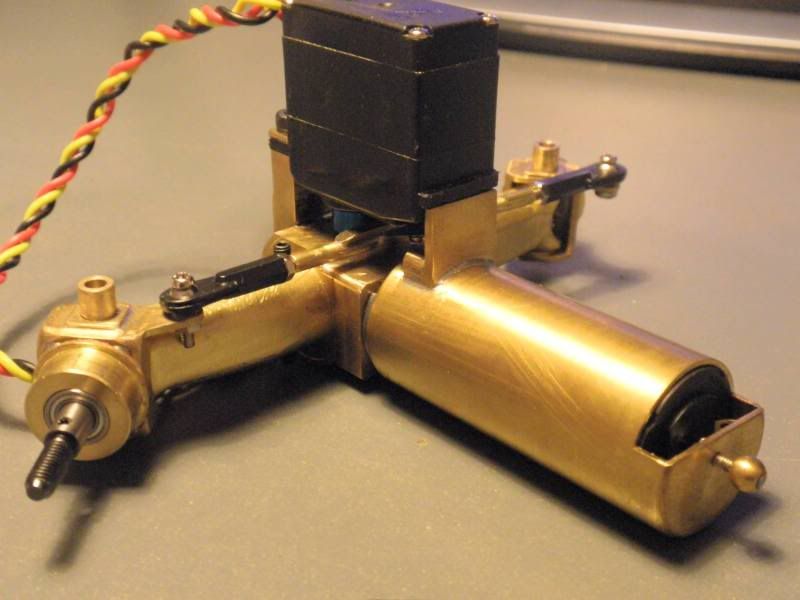

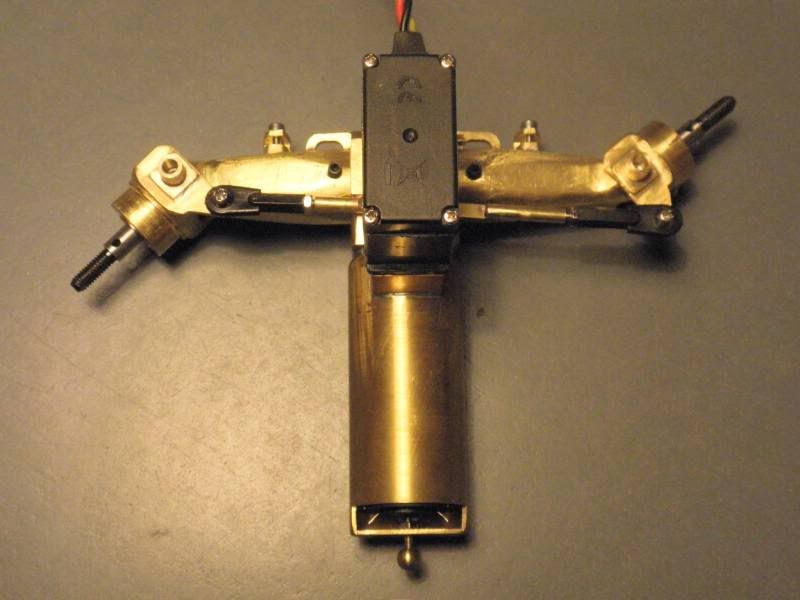

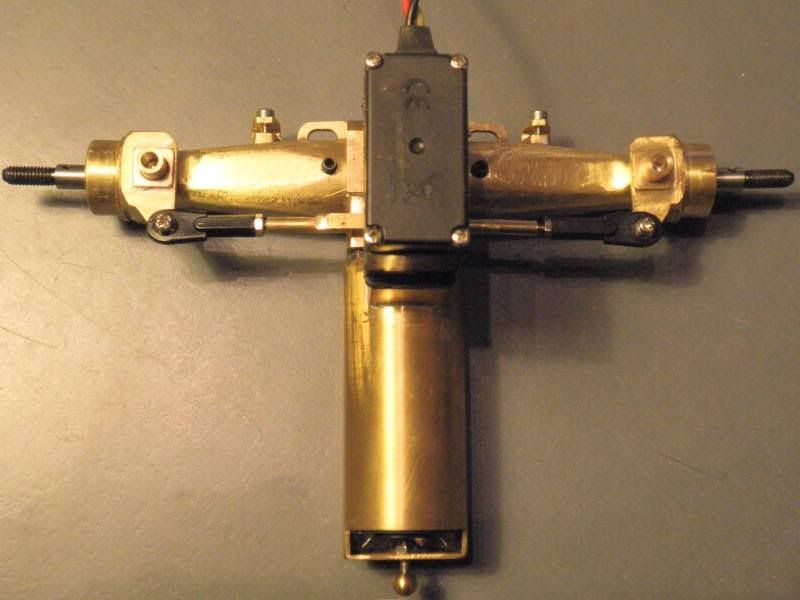

Here is an update to my 4WD John Deere 7x20 frontaxle.

Almost ready to paint, but there is still some touch ups to do. The little ball in front, fender brackets, wires + prepare the old wheels to the driveaxles.

Here is some photos.

Comments are welcome as usual.

Anders Kolpen

-

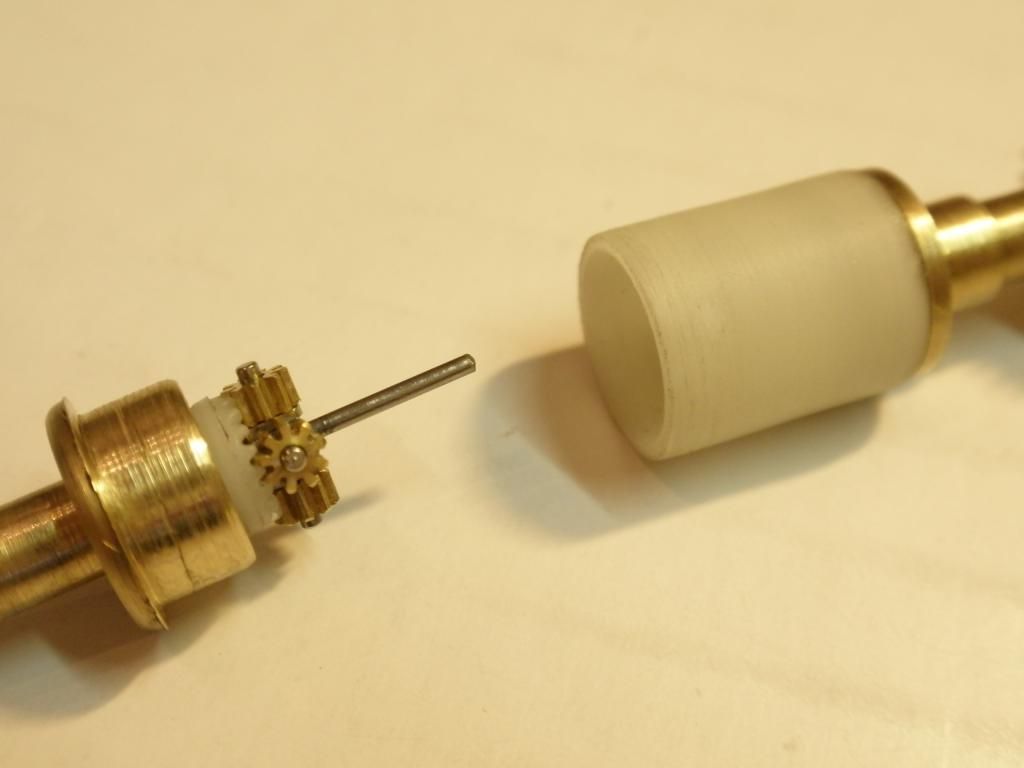

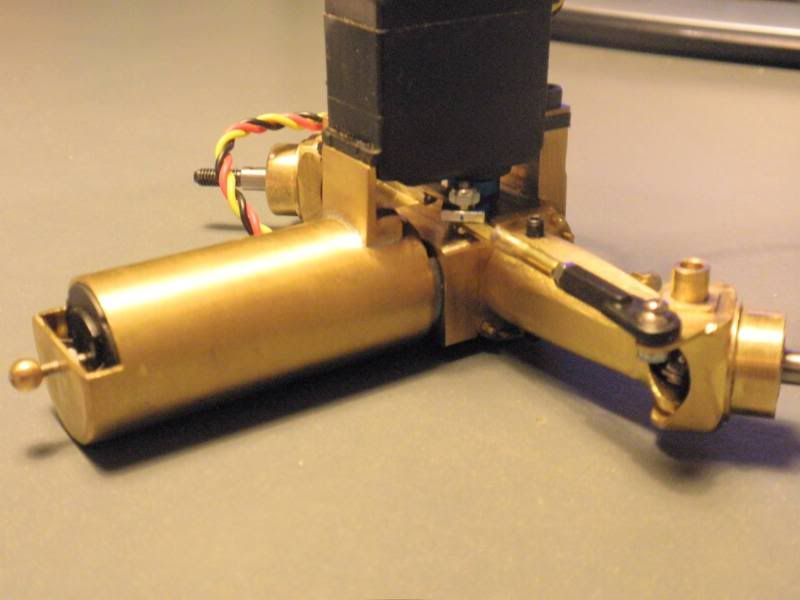

Here is a little update to the frontaxle I am building.

It's a little rough and square, but it is going in the right direction.

The ‘differential’ is done and ready to mount in when the housing is completely done. Still a few things to do on this part. I can’t wait to test this new axle on the tractor….

More to come…..

Anders Kolpen

-

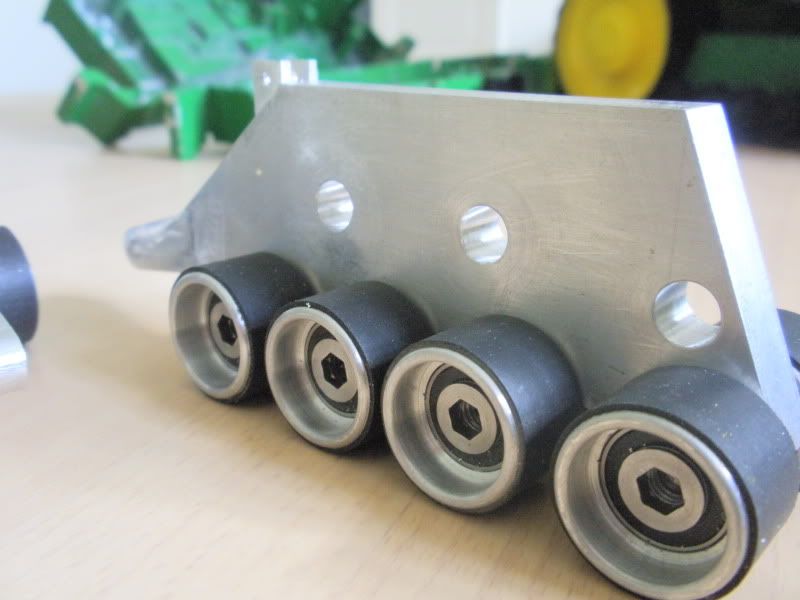

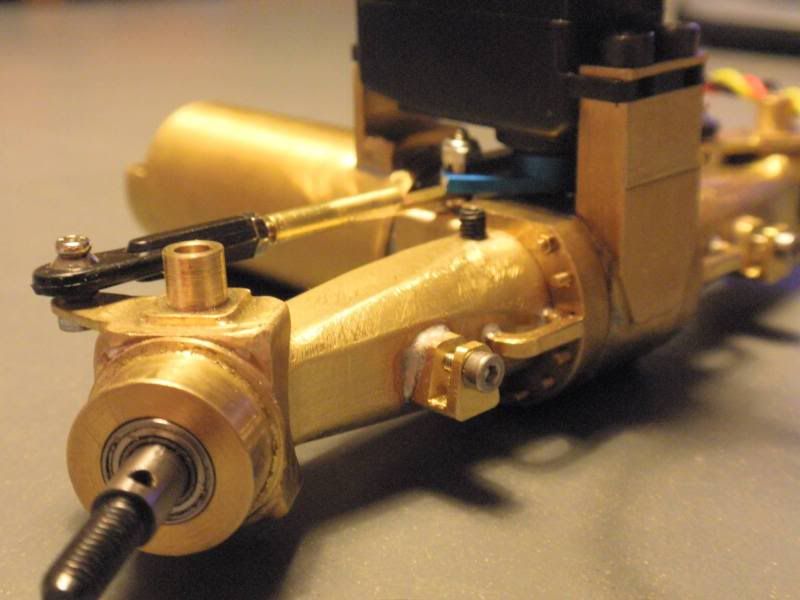

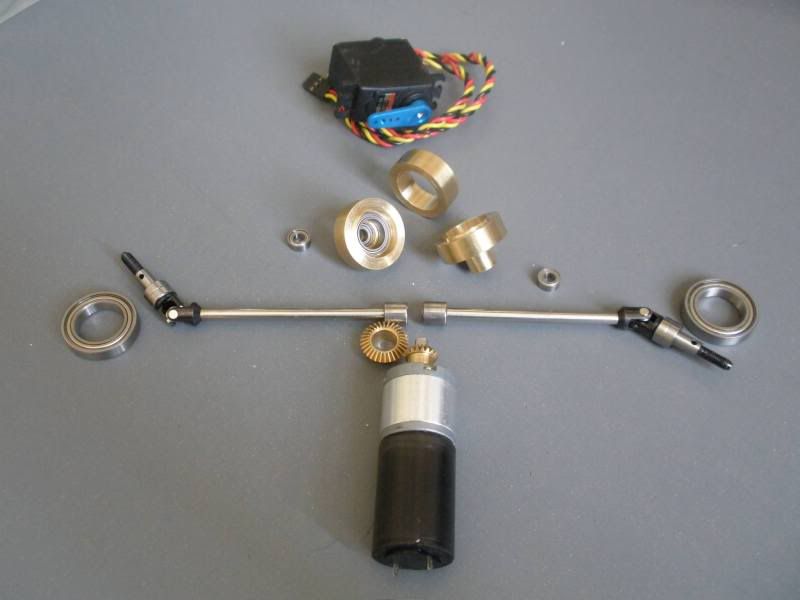

While I wait for some parts for the Kverneland plow, I thought I would start building a new frontaxle for the JD 7920.

The plow features a mechanical system that puts pressure to the frontaxle via the topshaft. Up to 1 pound of pressure just by pulling the plow….. !!!

All that would not be used at all with a normal 2WD tractor. So that triggered me to start building the new axle.

Some details.

The axle will have it’s own gearmotor. It have the exact same gearratio as the rearaxle but the front diff. is 1,5:1 and rearaxle is 2:1.

The differential works by 2 ‘one-way’ needlebearings. When it runs forward the axle is actually locked (diff. lock). But in turns the outer wheel spins faster than the innerwheel. (power to innerwheel only = 3WD). ‘One-way’ means that I will only have 4WD when it runs forward and 2WD in reverse.

The complete axle will feature 14 bearings in different sizes.

The basic diff is almost done, much more to come…..

Take care!

Anders Kolpen

-

-

That is a very nice project you are working on there!!

One thing though: Should you be the first to actually 'correct' the position of the front fenders?

I really dig these 8030 series tractors from ERTL, amazing attention to the detail. But I really don't get why they mounted the fenders so much 'over' the frontwheels.... ??

Am I crazy or did I have something right here?

Keep up the great work!

Anders

-

I wanted my John Deere tractor to drive more realistic. I have a super smooth motor (faulhaber) and ESC (servonaut) and Digital steering servos programmed to move very slow.

But the turning radius could be better and also a real JD tilts the wheels when turning... :trucker

So here is some progress pics from the build.

Camber angle is 5 dgr. and Caster angle is 12 dgr. to give the correct steering.

New inserts for the wheels were nescessary because the turningpoint is moved further inside the rims....

The fender brackets is also redesigned. John Deere calls the mounting 'pro pivot' as the fenders is allowed to turn when they hits the tractorframe. These do the same. Two square tubes are held together with a piece of shrink tube.....

Turning radius is cut down with 15cm..... to 37cm. Very close to the original, 1:1 scale.

Thanks for watching!

Anders Kolpen

Denmark

-

Here is a new video with my John Deere 7920 and a homemade 5 furrow reversible plow. All brass, only moldboards are plastic (from Bruder Lemken plow).

Tractor is a customized ERTL John Deere 7920 Collectors Edition.

Have a look

Click link to view the video:

Thank you

Anders Kolpen

Denmark

-

Ok so here is my new project.

I thought that the radio controlled John Deere 7920 (1/16) tractor could need a smaller turning radius.

Originally the frontaxle from ERTL is made to a very narrow frontwheel setup to follow the line of the inner rear duals.

So I desided to make a new axle, made for the wider setup.

So why not go green all the way.

I am about to convert the existing frontaxle from the ERTL tractor to a wide setup using John Deere's principles for the turning.

Everybody knows that when a Deere turns it tilts the wheels.

My axle has 5 degr. camber angle inward and 12 degr. caster angle backwards.

The axles at the ends looks bend, they are not, it's the light... :wink:

Next up is to make the turningparts and hubs and to mount the servo...

/anders

-

rc-traktoren@hotmail.de is the man with the chassis. At the moment he only makes this model, but more will come in the future. Unfortunatly in a bigger scale....

The ultimate kit for a big-hp BRUDER tractor would be the 4WD kit to build inside the Claas, JD 7930, FENDT.

It's also made in germany by Wachingers.

http://www.wachingers.de/mb/katalog/index.html >> Baus?tze und Modelle 1:12 >> Getriebe mit Zubeh?r....

Regards

Anders Kolpen

-

Thanks a lot! Nice to hear all your comments!

The Massey in the background is from a german guy. He makes the chassis (and sells them) to be decorated with any brand of small/compact Bruder etc. tractors hood and cab.

Yes, it pulls a set of rollers. Small and versatile but I don't know if it will be able to pull the bigger implements. But indeed a nice tractor.

I'm glad you all liked it!

Anders

-

Here is my tractor plowing in sand at the TRAKTORADO Toy Tractor Show in Husum, Germany.

The plow project was actually cancelled due to some issues with the moldboards and I should have made the mainframe from a tube instead of a solid bar.

So I just mounted 2 depthwheels to the plow to be able to use it in the weekend. But actually I was quite satisfied with the overall performance

and I should start a new plow project soon. In the works/mind is a Kverneland PB 100 semi mounted one-wheeled plow.

and I should start a new plow project soon. In the works/mind is a Kverneland PB 100 semi mounted one-wheeled plow.The tractor is in it's best shape at the moment!

No wheel slip really and super pulling torque. I added extra weight to the rearwheels. Now both wheels weigh 1600grams or 3.5lbs. Tractor in total is now up at 4100grams or 9 lbs. So no matter what it just grips to the soil and pull.....

No wheel slip really and super pulling torque. I added extra weight to the rearwheels. Now both wheels weigh 1600grams or 3.5lbs. Tractor in total is now up at 4100grams or 9 lbs. So no matter what it just grips to the soil and pull.....All in all I was just happy with tractor that day.

Enjoy the video!

/Anders Kolpen

-

Here is a little video of what I've been working on.

My JD 7920 has got sound. It's controlable from the transmitter and can be mixed over various functions. Ex. it runs idle but when I lower the rearhitch it rev's up to maximum....

The plow is red! that's how long I've got since last time....

\ I'll have it completely finished before sept. 1.st. where I'll be joining a show.

\ I'll have it completely finished before sept. 1.st. where I'll be joining a show. Watch the video and enjoy. I know it's nothing fancy, no edit, no outside in the dirt. Just simple footage, because of rain and lack of depth-wheel on the plow....

Thanks for watching!

Anders Kolpen

-

... then again their Claas Jaguar is marked as 1/16 but is too small for that size? Confused?, yes!

-

BRUDER Implements IS bigger.

I convert ERTL tractors to radio control to work and operate as the real one. As for ERTL like UH they don't offer too many implements for this size (1/16). Well, ERTL does, but not enough for the big horsepower newage tractors, which I am looking for.

That means I also have to look at BRUDER implements. I use the LEMKEN Smaragd grubber, looks realistic to my ERTL JD 7920. Wagons, harrows, rakes etc. is too big.... Maybe it's the lack of details/plastic build or maybe they missed something on the calculator.

Also SIKU Junior (not made anymore) is too big to be called 1/16.

I had some drawing for a frontlift printet in 1/16 scale from HeVa. The drawings matched the tractor very well (Ertl 1/16), that makes me sure to call ERTL for real 1/16 scale....

/Anders

-

Very good! That is really what I wanted to see. The packer is a top feature!

Better pictures please....

Well done!

Anders

-

That is probably the best looking conversion I have ever seen. So clean and original!!

Very nice work there.

Searching for some wheels

in Custom Model Methods/Tips/Help

Posted

Once again thank you all!! Fantastic to see how helpfull everyone is.

Well, as mentioned, the tractor-tread tire was spot on! But not convinced at the trailer tread tire....

If I may steal some more of your time I won't close this topic to see what else you can find!!

Dimensions, according to the tractor tread tire, is now 48-50mm.

Thank you a lot!

Anders Kolpen

Denmark